Center of Modern Control Techniques

and Industrial Informatics

Department of cybernetics and artificial intelligence (DCAI), FEEI, Technical University of Košice

Flexible Manufacturing System

|

Room:

|

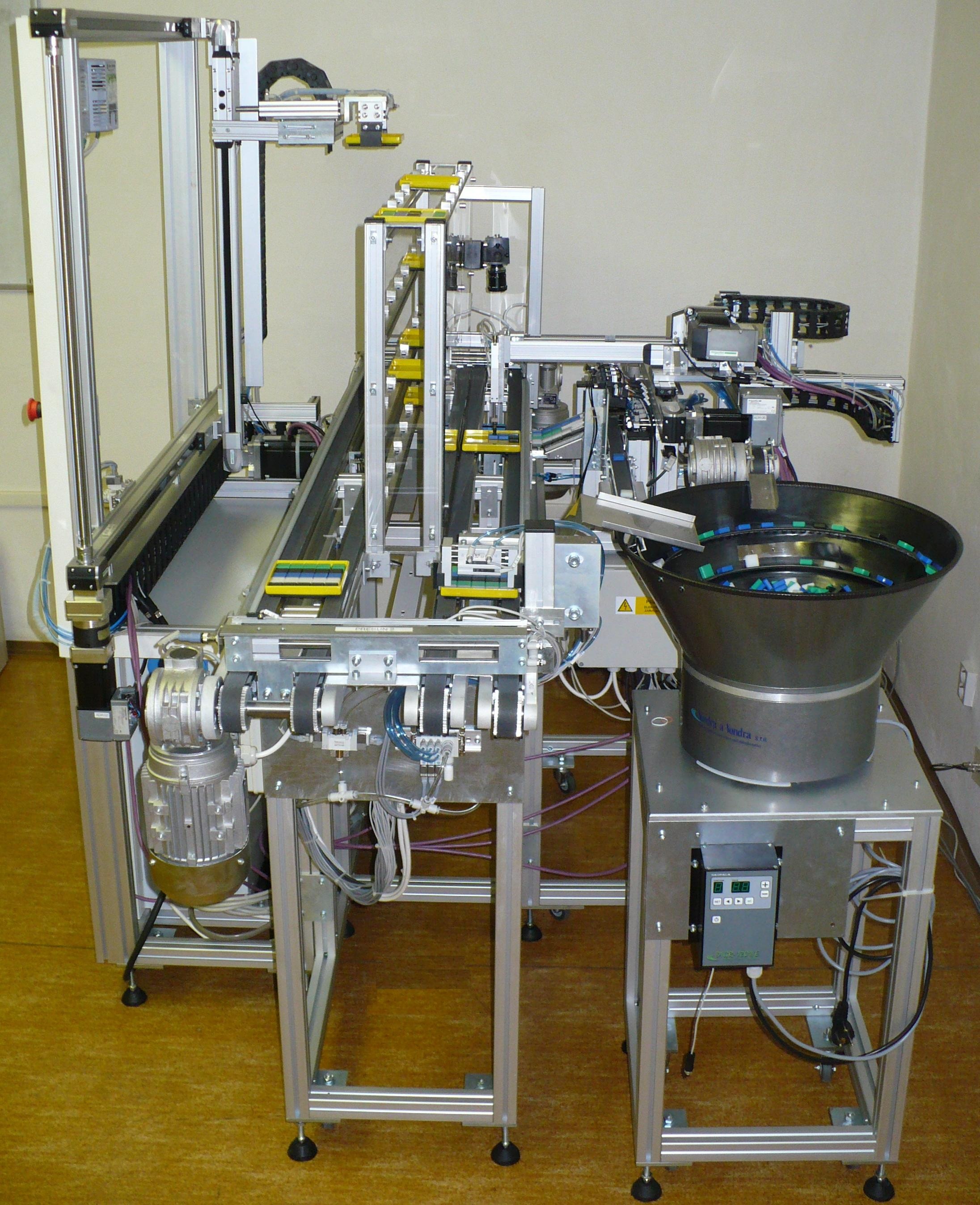

Brief description of the model

- fully automated model of a production line

- covers all five layers of the distributed control system

- consists of six posts

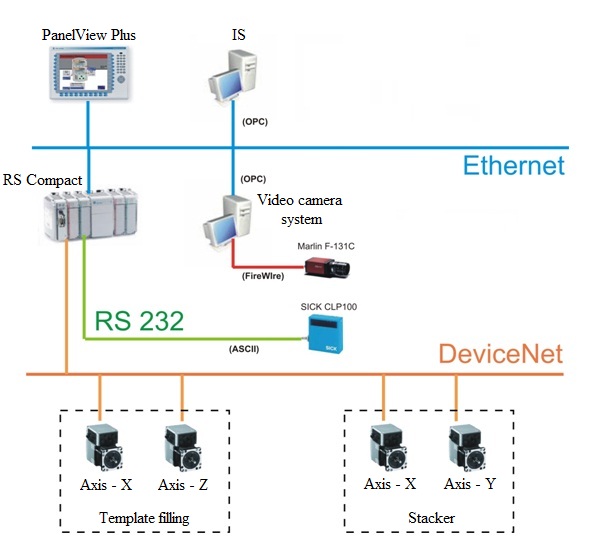

- the production line model uses four types of technological interfaces: Ethernet, DeviceNet, FireWire, RS-232

Gallery

|

|

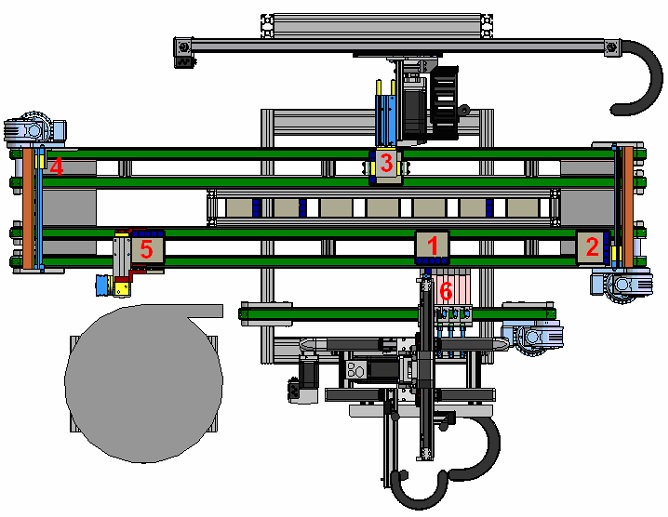

Mechanical design

- L32E CompactLogix control system

- two three-axis manipulators driven by three-phase stepper motors in two axes; the third axis is pneumatic

- two small and two large conveyor belts driven by AC motors

- CLP 100 bar code scanner connected to a PLC through the RS-232 interface

- Marlin F-131C color camera connected to a PC through FireWire

- KEYENCE CZ-H35S optical color sensor with KEYENCE CZ-V21AP evaluating instrument

- a vibrating stack with a control unit

- warehouse is permanently installed with 28 positions

- View 600 color touch panel allows local visualization

- the line includes a number of pneumatic actuators, inductive, resistive and optical sensors

Description of the Flexible Manufacturing System (FMS)

- FMS consists of 6 positions shown in the figure and described below

- the FMS is required to assemble a color pattern out of 25 colored marbles according to a specific order

- camera system uses an image recognition application to check the accuracy of the produced pattern

- the information system collects and evaluates orders, determines the production plan, allows stack tracking and FMS analysis

- the operator is able to control and manage production with local and remote visualization

- post 1: three-axis manipulator assembles the desired pattern

- post 2: after camera inspection, the template is moved to the first conveyor

- post 3: template is selected in the formation and storage of stock

- post 4: template is moved from the first conveyor to the second one

- post 5: full or poorly made template is tilted back into the reservoir

- post 6: blocks from a vibrating stack are sorted by color in small containers

courses

- Distributed Control Systems (1st grade master degree)

bachelor theses

- MARETTA, Ivan: Design and implementation of management of the production line PLC.

(supervisor: doc. Ing. Ján Jadlovský, consultant: Ing. Matej Čopík) - 2011 diploma theses

- BARAN, Miroslav: Proposal and implementation of information system for Flexible Manufacturing System.

(supervisor: Ing. Stanislav Laciňák) - 2010 - ČOPÍK, Matej: Proposal and implementation of flexible production system control.

(supervisor: Ing. Stanislav Laciňák) - 2010 - CHOCHRUN, Peter: Design and implementation of governance model production line PLC.

(supervisor: doc. Ing. Ján Jadlovský, consultant: Ing. Matej Čopík) - 2011 - ŠILON, Marián: Design and implementation of communication between the model and database management system.

(supervisor: doc. Ing. Ján Jadlovský, consultant: Ing. Matej Čopík) - 2011 - ŠEPENTÁL, Patrik: The application of recognition of still images for production lines.

(supervisor: doc. Ing. Ján Jadlovský, consultant: Ing. Matej Čopík) - 2011 dissertation theses

- ILKOVIČ, Ján:

Modeling and diagnostic of manipulating and robotized systems

(supervisor: doc. Ing. Ján Jadlovský, CSc.) - 2012 (in preparation) - ČOPÍK, Matej:

Methodology for the design and implementation of production lines with to optimize production time

(supervisor: doc. Ing. Ján Jadlovský, CSc.) - 2013 (in preparation) - PAPCUN, Peter:

Modeling and optimization of robotic and technological production lines

(supervisor: doc. Ing. Ján Jadlovský, CSc.) - 2014 (in preparation) publications

- 2012

-

2011

-

ČOPÍK, M. - ILKOVIČ, J.: Proposal control of manipulators controlled via technological network DeviceNet. In: SCYR 2011 : 11th Scientific Conference of Young Researchers of Faculty of Electrical Engineering and Informatics Technical University of Košice : proc. - Košice : FEI TU, 2011 S. 335-338. - ISBN 978-80-553-0644-5.

ILKOVIČ, J. - ČOPÍK, M. - JADLOVSKÝ, J. – LACIŇÁK, S.: Technological level of flexible manufacturing system control. In: Acta Electrotechnica et Informatica., ročník 11, č. 1 (2011) s. 20-24. - ISSN 1338-3957.

ILKOVIČ, J. - ČOPÍK, M. - KAROĽ, T: The assembly line model at Department of Cybernetics and Artificial Intelligence. In: SCYR 2011 : 11th Scientific Conference of Young Researchers of Faculty of Electrical Engineering and Informatics Technical University of Košice : proc. - Košice : FEI TU, 2011 S. 373-376. - ISBN 978-80-553-0644-5.

-

2010

-

CHOVAŇÁK, J. - ILKOVIČ, J. - LACIŇÁK, S. - JADLOVSKÝ, J.: A shelf interpolator model distributed control system. In: SAMI 2010 : 8th International Symposium on Applied Machine Intelligence and Informatics : January 28-30, 2010, Herľany, Slovakia. - S. l. : IEEE, 2010 S. 311-313. - ISBN 978-1-4244-6423-4.

JADLOVSKÝ, J. - LACIŇÁK, S. - CHOVAŇÁK, J. - ILKOVIČ, J.: Design DCS for FMS. In: Kybernetika a informatika : zborník abstraktov : medzinárodná konferencia : Vyšná Boca, Slovenská republika, 10.-13. február 2010. - Bratislava : STU, 2010 S. 1-6. - ISBN 978-80-227-3241-3.

ČOPÍK, M. - JADLOVSKÝ, J. – LACIŇÁK, S.:Design and realization of information system for Flexible Manufacturing System. In: Electrical Engineering and Informatics: Proceeding of the Faculty of Electrical Engineering and Informatics of the Technical University of Košice. - Košice : TU, 2010 S. 556-560. - ISBN 978-80-553-0460-1.

ČOPÍK, M. - JADLOVSKÝ, J. – LACIŇÁK, S.:Control design and realizastion of Flexible Manufacturing System. In: Electrical Engineering and Informatics: Proceeding of the Faculty of Electrical Engineering and Informatics of the Technical University of Košice. - Košice : TU, 2010 S. 561-564. - ISBN 978-80-553-0460-1.

Description of posts

Interfaces connections of FMS:

Using the model in pedagogy

Using model in the research

Profile

Infrastructure

Laboratories

Members

Courses

Models

- 32-bit single-chip product

- Flexible Assembly Company

- Ball & Plate CE151

- Ball & Plate B&P_KYB

- Helicopter

- Hydraulic system

- Video camera system

- Crossroad model

- Rotary pendulum

- Magnetic levitation

- Khepera II Mobile robot (simulation approach)

- Motor & frequency converter

- Tracked mobile robot

- Flexible Manufacturing System

- Shelf stacker

- Mitsubishi robot

- SEF robot

- Robot soccer player for MiroSot category

- Robotized workplace

- Light system

- Tensometric (strain) scales

Research

CERN

Gallery

Partners